Montgomery County, MD Directional Drilling AI

Montgomery County, MD Underwater Utility Directional Bore

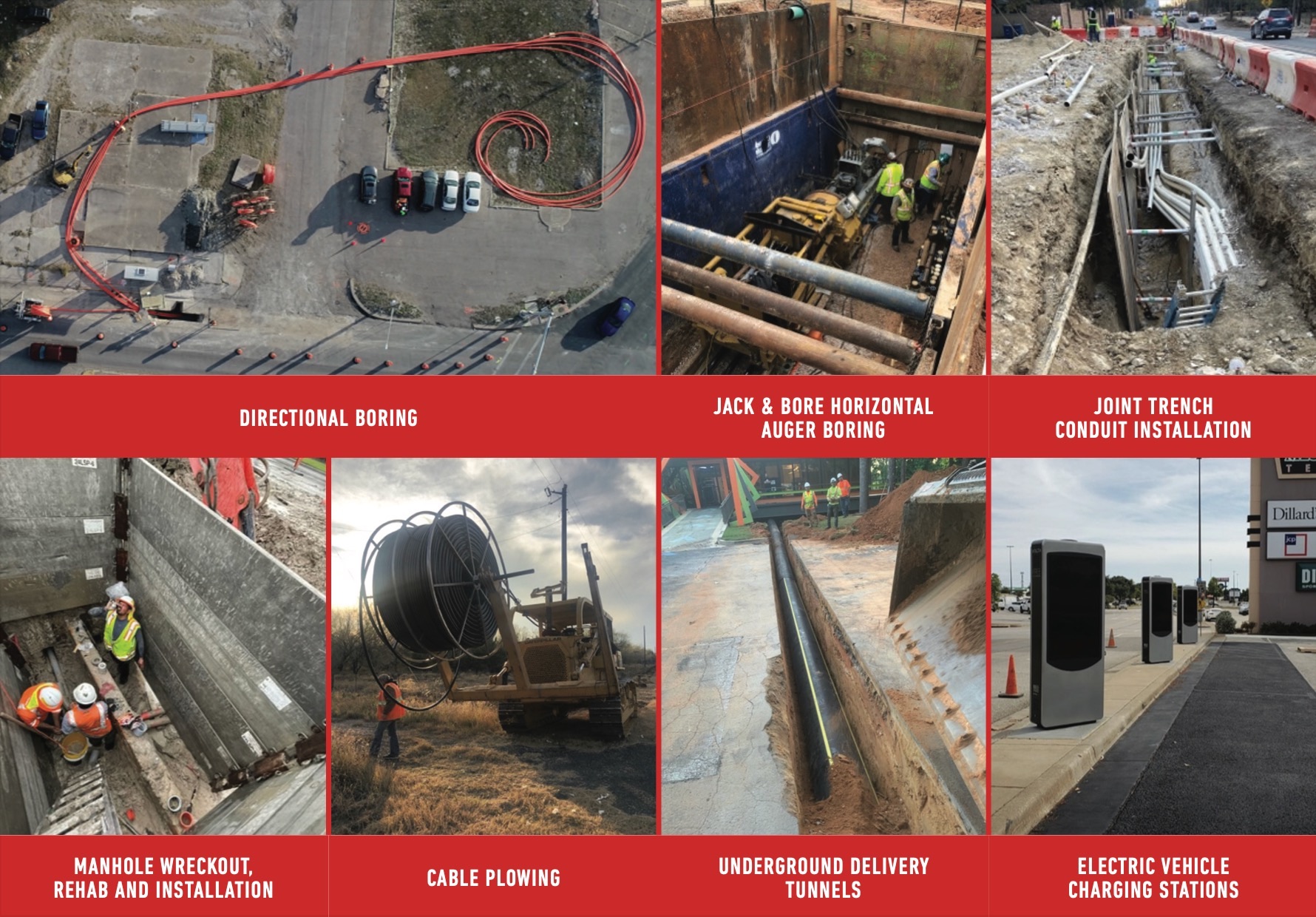

Directional Drilling AI provides Montgomery County, MD with underground and underwater utility infrastructure construction services via Horizontal Auger Boring, Tunneling and Horizontal Directional Drilling (HDD) more commonly called Directional Boring.

We provide underground utility construction services specializing in the underground boring of utility pipelines for electric power, solar, wind, oil, gas, petroleum, steam, security, telephone, satellite, cable, TV, Internet, wi-fi, fiber optic, sewer, drain, water and irrigation crossings.

As Montgomery County, MD directional boring contracting experts, we excavate an opening beneath the ground without disturbing the surface to bore underground pipes for utility runs of all types of lengths and diameters both large and small.

From electrical to fiber optic lines, oil and gas pipelines, sewer lines and water mains, our Montgomery County, MD boring contracting team uses accepted directional boring techniques to place HDPE, PVC and steel pipe, conduit and cables under almost any surface like concrete slabs, driveways, sidewalks, walkways and roads in diverse terrains like dirt, clay, rock, cobblestone and even sand.

We have decades of directional drilling experience and have bored and installed utility pipelines under trees, under county roads, under bridges, under railroad tracks and even under lakes and rivers.

Montgomery County, MD Horizontal Auger Boring

We use state of the art horizontal auger boring equipment and experienced auger boring crews for commercial and municipal underground pipe installation projects in Montgomery County, MD and beyond.

Horizontal auger boring (HAB), also known as earth boring or jack and bore, may be the best trenchless option for pipe lengths up to 500 feet and diameters of up to 60 inches in a variety of soil conditions. Horizontal auger boring can be used to install pipes in transitioning ground conditions and, in many cases, can have lower overall costs when compared to other trenchless methods.

Horizontal auger boring uses a revolving cutting head that is located at the leading end of an auger assembly to excavate the soil. Common practice is to jack steel casing carrier pipe through the excavated hole as it is being bored. The spoil is then transported back to the shaft area by the rotation of the helical auger flights within the steel pipe casing.

State and municipal street, traffic and drainage projects as well as railways in Montgomery County, MD may require their pipelines be auger bored, jack and bored or tunneled over any other method.

Auger boring is a well established means of trenchless installation for these types of on grade crossings that utilize steel casing where ground settlement of any kind is not permitted. By continuously supporting the excavated ground with steel casing pipe, the possibility of lost ground and settlement is diminished. Boring in hard rock like limestone and granite ranging up to 35,000 psi can also be accomplished with this method.

Montgomery County, MD Railroad Auger Bore

The railroad system continues to be a major component in the transportation of raw materials used for projects nationwide. As the current railway lines age, and demand grows, railroad’s need for widening and improvement projects on existing tracks has increased. These projects for railroad companies like Union Pacific, BNSF, CSX and Norfolk Southern are often in remote locations and present challenges to contractors in complying with railroad protocol for working around active rail tracks.

Our horizontal auger boring experts have successfully performed auger bores underneath existing railroad tracks to install steel casing used for new drainage.

With auger boring, often referred to as 'jack and bore', our experts simultaneously ‘jack’ casing while rotating helical augers within the casing remove spoils. A cutting head is attached to the 'lead' auger and can protrude just ahead, sit flush, or sit within the casing depending on the project requirements. Hydraulic jacks located on the bore machine in the sending shaft provide the thrust that pushes the steel casing through the ground. The rotating augers then carry the spoil to the back of the steel casing pipe for removal by muck bucket, excavator or conveyor.

While auger boring is a familiar trenchless method, ground conditions can present problems that prevent this method from being used. Running sands and boulders often prevent projects from utilizing horizontal auger boring. Other solutions such as pipe ramming, hand tunneling or directional drilling may instead be applied.

The auger boring process can be used for as small as a 6" diameter line to as large as a 72" diameter pipe. Our core horizontal auger boring focus in Montgomery County, MD is the installation of 24" diameter to 48" diameter pipes.

Montgomery County, MD Utility Directional Drilling AIs

Utility directional boring begins with the drilling of a small diameter pilot hole directed to and along a desired design profile using flexible drill rods. Sub-site electronics are used to monitor and track the bore location through a sensor located in the bore head below the surface. Directional changes are made to the drilling alignment and direction with a bore head, which is offset slightly from the directional drill rods. Through small adjustments by the drilling operator, steering corrections throughout the bore can be made (for example, around and under tree roots, boulders, existing buried utilities or private property). A special drilling "mud" technology like bentonite, borrowed from the oil and gas industry, is introduced into the bore hole to prevent it from caving in as well as providing a lubricant and flushing medium for the bore hole cuttings.

Following advancement of the pilot hole, a back reamer is attached and pulled back though the pilot hole in order to achieve the required bore hole diameter for the product pipe to be installed. Pipe or casing may then be pulled through the borehole into a position for the required connections to be made.

This form of trenchless utility pipe installation is often better for the environment and can save Montgomery County, MD property owners’ time and money by significantly reducing the surface disruption costs often associated with open cut landscape, asphalt trenching and concrete sawing.

Benefits of Directional Boring UtilitiesAvoid damage to your property (buildings, landscaping and hardscapes)

A trenchless (no-dig) option for establishing new utility lines

Significant cost savings compared to open-cut utility line installation methods

Shorter utility project completion times

Environmentally friendly

Having decades of directional drilling expertise, our boring contractor team can - whether through horizontal directional drilling (HDD), horizontal auger boring or mircro-tunneling services - successfully bring your next Montgomery County, MD underground infrastructure construction project in on time and within budget.

Montgomery County, MD Call Now!

Montgomery County, MD Boring Company | Montgomery County, MD Auger Boring Companies | Montgomery County, MD Directional Boring | Montgomery County, MD Utility Crossings | Montgomery County, MD HDD | Montgomery County, MD Horizontal Directional Drilling | Montgomery County, MD Trenchless | Montgomery County, MD Underground Construction

In Montgomery County, MD our services are categorized under the following codes:

NAICS Code 238910 Boring, for building construction NAICS Codes 237990 Horizontal Directional Drilling (underground cable, pipeline, sewer/water installation)

CSI Code: Common Work Results for Utilities –

33 05 23.13 Utility Horizontal Directional Drilling

33 05 23 Trenchless Utility Installation

33 05 23.13 Utility Horizontal Directional Drilling

33 05 23.16 Utility Pipe Jacking

33 05 23.19 Microtunneling

33 05 23.23 Utility Pipe Ramming

33 05 23.26 Utility Impact Moling

31 71 19 Tunnel Excavation by Tunnel Boring Machine

41 33 16 Boring Equipment

© 2017 Best Boring Company, LLC

Pulling For You ™